主要国家级项目:

序号 |

项目题目 |

年度 |

来源 |

经费(万元) |

1 |

数据驱动的不锈钢研发-生产-应用技术 |

2022-2025 |

科技部国家重点研发计划课题 |

480 |

2 |

重点基础材料技术提升与产业化超高强度汽车用钢 |

2017-2020 |

科技部国家重点研发计划课题 |

400 |

3 |

高性能超高强汽车用钢关键制造技术基础研究 |

2017-2021 |

科技部国家重点研发计划 |

350 |

4 |

基于高温合金增材制造高通量技术的数据库建立及耦合式挖掘 |

2021-2025 |

科技部国家重点研发计划课题 |

335 |

5 |

面向工业场景的汽车用高强钢多模态数据挖掘与机理反向深化 |

2022-2026 |

国家自然科学基金联合基金项目 |

280.5 |

6 |

XXXXXXX |

2017-2020 |

军委装备发展部共性技术预研项目 |

280 |

7 |

数据驱动的多目标组织性能预测与优化 |

2023-2026 |

科技部国家重点研发计划 |

276 |

8 |

超高强汽车钢相变行为及亚稳组织综合调控与力学响应 |

2019-2022 |

国家自然科学基金联合重点项目 |

250 |

9 |

材料基因工程基于高端装备制造业的特殊用钢 |

2017-2020 |

科技部国家重点研发计划子课题 |

180 |

10 |

先进钢铁材料的集成计算设计 |

2017-2020 |

国家自然科学基金优秀青年基金项目 |

130 |

11 |

图神经网络辅助金属加工硬化预测的多尺度方法:以时效硬化铝合金为例 |

2024-2028 |

国家自然科学基金国际(地区)合作(香港) |

100 |

12 |

基于热/动力学协同的非平衡相变组织预测 |

2017-2022 |

国家自然科学基金重大项目子课题 |

90 |

13 |

薄板坯连铸连轧汽车用钢集成设计 |

2022-2025 |

科技部国家重点研发计划子课题 |

80 |

14 |

耦合人工智能算法和物理冶金模型 的亚稳奥氏体调控 |

2019-2022 |

国家自然科学基金国际合作项目 (英国) |

80 |

15 |

高屈服高强塑积热轧中锰汽车钢相变机理与组织调控 |

2016-2020 |

国家自然科学基金面上项目 |

76.8 |

16 |

亚稳奥氏体不锈钢多级纳米组织构筑与多阶段应变硬化机理 |

2021-2025 |

国家自然科学基金面上项目 |

64 |

17 |

亚稳奥氏体热/机械稳定性的热力学与相变共性机制与调控基础 |

2022-2026 |

国家自然科学基金面上项目 |

58 |

18 |

层状亚稳奥氏体热稳定性和机械稳定性及其关联性研究 |

2019-2021 |

国家自然科学基金青年基金 |

24 |

19 |

亚稳奥氏体热/机械稳定性基础及力学响应 |

2020-2022 |

国家自然科学基金国际合作项目 (俄罗斯) |

15 |

20 |

超快速退火先进高强钢的相变行为及力学响应 |

2021-2022 |

国家自然科学基金国际合作项目 (比利时) |

10 |

主要企业合作项目:

序号 |

项目题目 |

年度 |

来源 |

1 |

XXXXXX |

2024-2026 |

中国航发北京航空材料研究院 |

2 |

多重异构轻质高强钢的制备及强塑性机理研究 |

2024-2025 |

宝山钢铁股份有限公司 |

3 |

耐海洋微生物腐蚀和生物被膜黏附的新型钢铁材料 |

2022-2024 |

中国宝武钢铁集团有限公司 |

4 |

双相钢连铸浇次头坯热轧边裂、表裂的改善技术开发 |

2022-2024 |

振石集团东方特钢有限公司 |

5 |

基于机器学习算法的检测方案优化设计 |

2022-2022 |

松山湖材料实验室 |

6 |

物理冶金原理指导的Q&P钢高通量数据挖掘与智能化性能预测 |

2022-2024 |

鞍钢集团北京研究院 |

7 |

超高强度一体化门环材料及成型技术开发 |

2021-2023 |

本钢板材股份有限公司 |

8 |

热轧抗氧化免涂层热成型钢产品开发 |

2020-2022 |

本钢板材股份有限公司 |

9 |

基于物理冶金原理的工业大数据挖掘与智能制造 |

2019-2022 |

本钢板材股份有限公司 |

10 |

高强镀锌QP钢系列化开发 |

2018-2022 |

本钢板材股份有限公司 |

代表性论文

1. Transitions in the thermal stability of pre-strained austenite – competing effects between defect density and slip band spacing ,Scripta Materialia 223(2023).

1. Building a quantitative composition-microstructure-property relationship of dual-phase steels via multimodal data mining,Acta Materialia 252(2023).

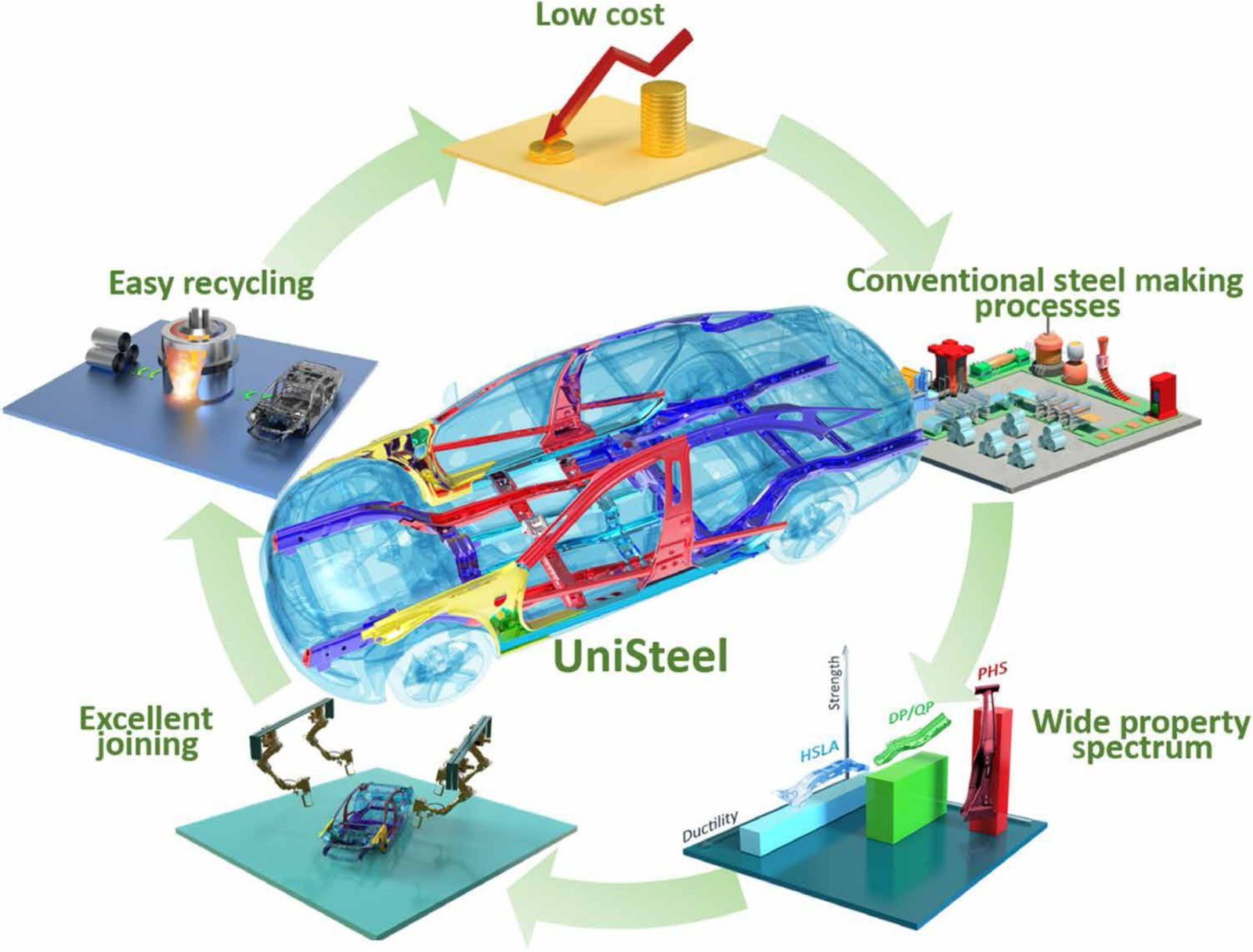

2. Q. Lu, Q. Lai, Z. Chai, X. Wei, X. Xiong, H. Yi, M. Huang, W. Xu, J. Wang, Revolutionizing car body manufacturing using a unified steel metallurgy concept, Science Advances 7(49) (2021).

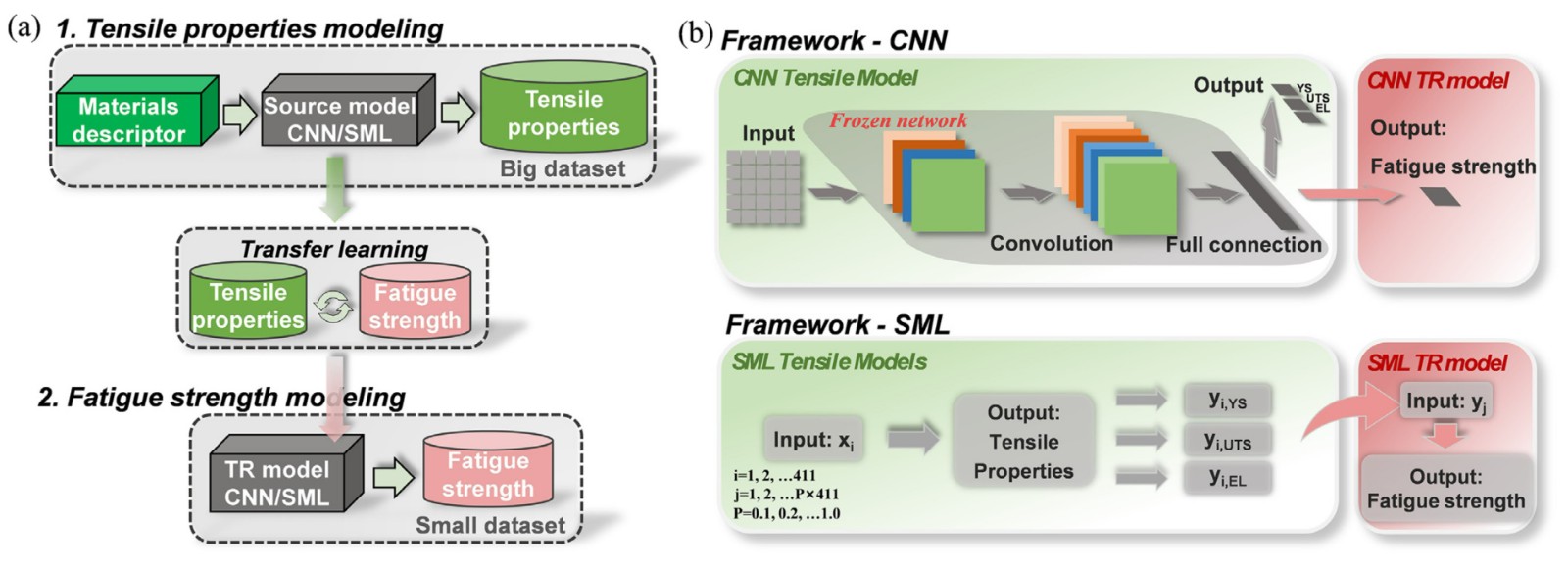

3. X. Wei, S. van der Zwaag, Z. Jia, C. Wang, W. Xu, On the use of transfer modeling to design new steels with excellent rotating bending fatigue resistance even in the case of very small calibration datasets, Acta Mater 235 (2022).

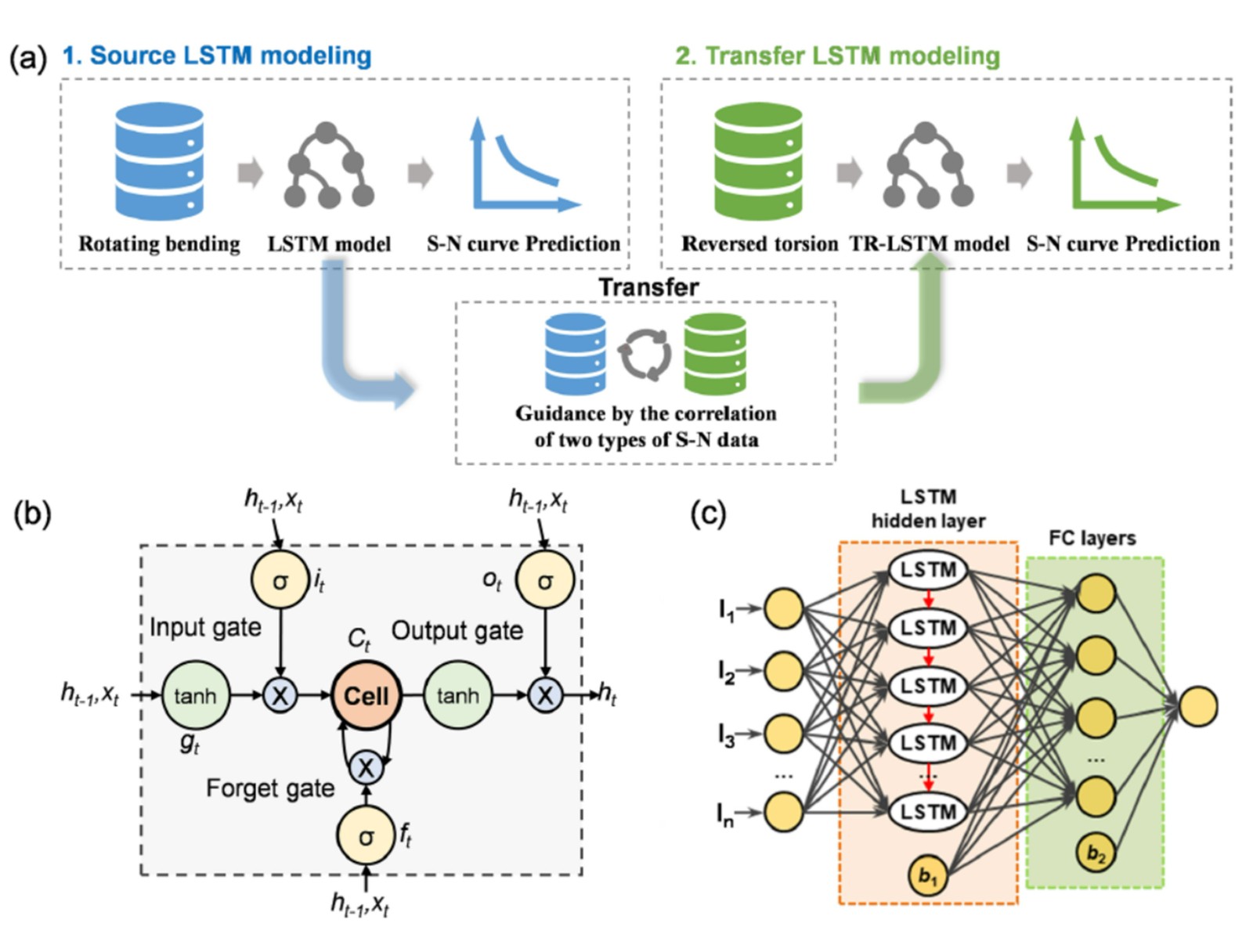

4. X. Wei, C. Zhang, S. Han, Z. Jia, C. Wang, W. Xu, High cycle fatigue S-N curve prediction of steels based on transfer learning guided long short term memory network, Int J Fatigue 163 (2022).

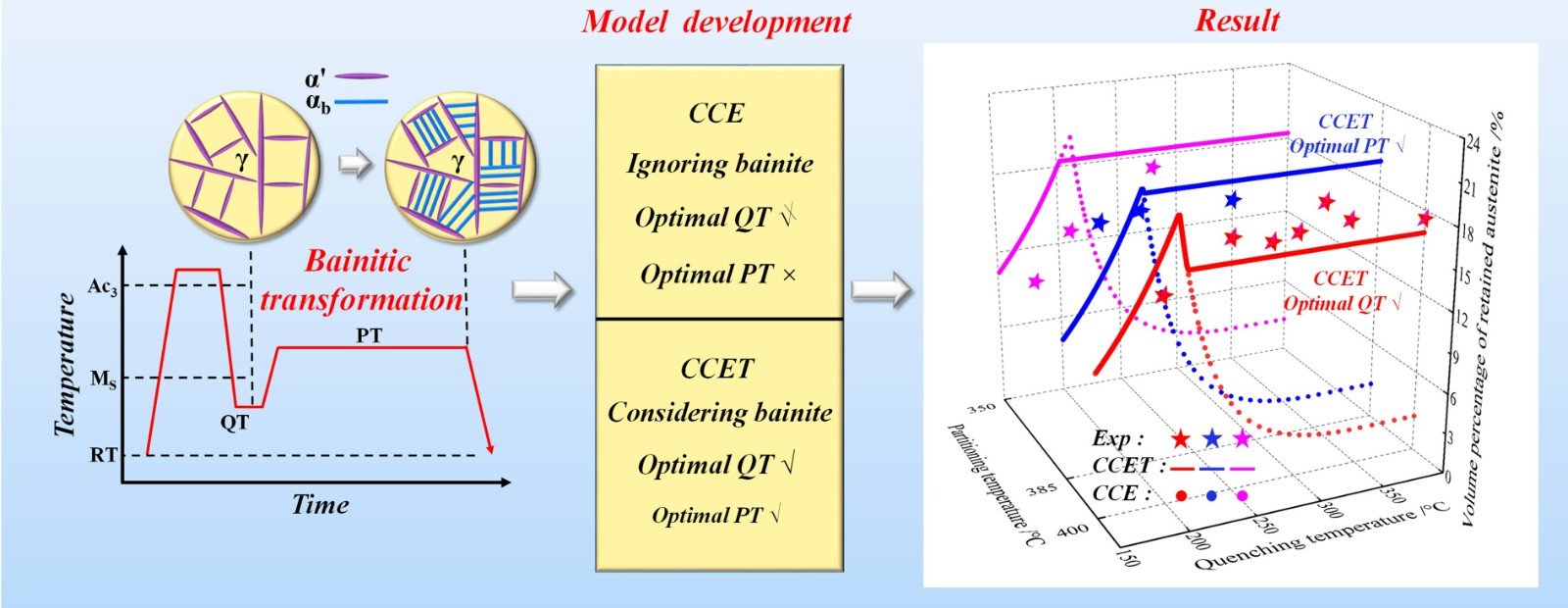

5. Y. Li, S. Chen, C. Wang, D.S. Martín, W. Xu, Modeling retained austenite in Q&P steels accounting for the bainitic transformation and correction of its mismatch on optimal conditions, Acta Mater 188 (2020) 528-538.

6. C. Shen, C. Wang, X. Wei, Y. Li, S. van der Zwaag, W. Xu, Physical metallurgy-guided machine learning and artificial intelligent design of ultrahigh-strength stainless steel, Acta Mater 179 (2019) 201-214.

近三年发表论文

2023年:

T. Zhang, Y. Wang, C. Zhang, L. Wang, H. Di, W. Xu, High cycle fatigue properties and fatigue crack propagation behavior of a bainite railway axle steel, International Journal of Fatigue 172 (2023).

H. Zhang, L. Wang, J. Hu, G. Wang, W. Xu, Optimum Wear Resistance Achieved by Balancing Bulk Hardness and Work-Hardening: A Case Study in Austenitic Stainless Steels, Tribology Letters 71 (2023).

J. Yuan, M. Huang, Y. Li, L. Wang, H. Li, W. Xu, Revealing the grain size-dependent twinning variants and the associated strengthening mechanisms in a carbon-free austenitic steel, Materials Science and Engineering A 864 (2023).

H. Yu, S. Yang, J. Shao, D. San-Martín, W. Xu, Prolonged creep lifetime of ferritic self-healing steels achieved by offline healing treatment, Materials Science and Engineering A 873 (2023).

X. Yan, J. Hu, X. Zhang, W. Xu, Macroscopic and nanoscale investigation of the enhanced wear properties of medium-Mnsteel processed via room-temperature quenching and partitioning, Wear 522 (2023).

D. Ren, C. Wang, X. Wei, Q. Lai, W. Xu, Building a quantitative composition-microstructure-property relationship of dual-phase steels via multimodal data mining, Acta Materialia 252 (2023).

G. Dong, J. Wang, L. Wang, C. Wang, J. Hu, W. Xu, Transitions in the thermal stability of pre-strained austenite-competing effects between defect density and slip band spacing, Scripta Materialia 223 (2023).

Y. Chen, H. Yu, Y. Chen, H. Di, W. Xu, The strengthening effects and mechanisms of alloying elements on interfaces for multiphase Ni-based superalloys: A first-principles study, Journal of Materials Research and Technology 23 (2023) .

Z. Chai, L. Wang, Z. Wang, Q. Lu, J. Hu, W. Sun, J. Wang, W. Xu, Cr-enriched carbide induced stabilization of austenite to improve the ductility of a 1.7 GPa−press-hardened steel, Scripta Materialia 224 (2023).

Z. Chai, Q. Lu, S. Tedesco, M. Shi, J. Coryell, L. Reini, Q. Lai, J. Wang, L. Wang, W. Xu, Investigation on Mechanical Properties and Oxidation Behavior of 1.2 and 1.7 GPa Grades Coating-Free Press-Hardened Steels, Metals 13 (2023).

Z. Chai, Q. Lu, J. Hu, L. Wang, Z. Wang, J. Wang, W. Xu, Effect of retained austenite on the fracture behavior of a novel press- hardened steel, Journal of Materials Science and Technology 135 (2023) .

2022年:

X. Wei, S. van der Zwaag, Z. Jia, C. Wang, W. Xu, On the use of transfer modeling to design new steels with excellent rotating bending fatigue resistance even in the case of very small calibration datasets, Acta Mater 235 (2022).

X. Wei, C. Zhang, S. Han, Z. Jia, C. Wang, W. Xu, High cycle fatigue S-N curve prediction of steels based on transfer learning guided long short term memory network, Int J Fatigue 163 (2022).

Y. Chen, C. Wang, W. Xu, The Influence of Alloying Segregation on Zinc-Induced Embrittlement at the α/γ-Fe Interface, Metall Mater Trans A 53(5) (2022) 1604-1612.

M. Huang, C. Wang, L. Wang, J. Wang, A. Mogucheva, W. Xu, Influence of DIMT on impact toughness: Relationship between crack propagation and the α′-martensite morphology in austenitic steel, Mater Sci Eng A 844 (2022).

M. Huang, C. Wang, X. Zhu, L. Wang, A. Mogucheva, W. Xu, Twin Instability and Its Effect on the Dislocation Behavior of UFG Austenitic Steel Under Charpy Impact Test, Metall Mater Trans A 53(6) (2022) 1921-1927.

M. Huang, L. Wang, C. Wang, A. Mogucheva, W. Xu, Characterization of deformation-induced martensite with various AGSs upon Charpy impact loading and correlation with transformation mechanisms, Mater Charact 184 (2022).

M. Huang, J. Yuan, J. Wang, L. Wang, A. Mogucheva, W. Xu, Role of martensitic transformation sequences on deformation-induced martensitic transformation at high strain rates: A quasi in-situ study, Mater Sci Eng A 831 (2022).

H. Li, Y. Li, J. Huang, C. Shen, C. Wang, T. Jing, Z. Liu, W. Xu, Physical Metallurgy Guided Industrial Big Data Analysis System with Data Classification and Property Prediction, STEEL RES INT (2022).

Y. Li, L. Wang, K. Zhu, C. Wang, W. Xu, An integral transformation model for the combined calculation of key martensitic transformation temperatures and martensite fraction, Materials and Design 219 (2022).

X. Peng, L. Wang, W. Xu, Z. Liang, Crystal Orientation Dependence of the Portevin–Le Chatelier Effect in Instrumented Indentation: A Case Study in Twinning-Induced Plasticity Steels, Metals 12(3) (2022).

C. Wang, D. Ren, Y. Li, X. Wang, W. Xu, Prediction of Deformation-Induced Martensite Start Temperature by Convolutional Neural Network with Dual Mode Features, Materials 15(10) (2022).

C. Wang, X. Wei, D. Ren, X. Wang, W. Xu, High-throughput map design of creep life in low-alloy steels by integrating machine learning with a genetic algorithm, Materials and Design 213 (2022).

C. Wang, K. Zhu, P. Hedström, Y. Li, W. Xu, A generic and extensible model for the martensite start temperature incorporating thermodynamic data mining and deep learning framework, Journal of Materials Science and Technology 128 (2022) 31-43.

H. Yu, J. Liang, Z. Bi, J. Li, W. Xu, Computational Design of Novel Ni Superalloys with Low Crack Susceptibility for Additive Manufacturing, Metall Mater Trans A 53(6) (2022) 1945-1954.

Y. Zhang, W. Xu, G. Zhang, W. Tao, S. Yang, Mechanical Behavior and Failure Mechanism of Q&P980 Steel During In Situ Post-Weld Heat Treatment (PWHT) Resistance Spot Welding, Metall Mater Trans A 53(3) (2022) 794-809.

Z. Zhang, S. Liu, Y. Zhang, C. Wang, S. Zhang, Z. Yang, W. Xu, Optimization of low-power femtosecond laser trepan drilling by machine learning and a high-throughput multi-objective genetic algorithm, Opt Laser Technol 148 (2022).

H. Chen, W. Xu, Q. Luo, Q. Li, Y. Zhang, J. Wang, K.C. Chou, Thermodynamic prediction of martensitic transformation temperature in Fe-C-X (X=Ni, Mn, Si, Cr) systems with dilatational coefficient model, Journal of Materials Science and Technology 112 (2022) 291-300.

W. Chen, H. Chen, C. Wang, W. Xu, Q. Luo, Q. Li, K. Chou, Effect of Dilatational Strain Energy of Fe-C-Ni System on Martensitic Transformation, Jinshu Xuebao/Acta Metallurgica Sinica 58(2) (2022) 175-183.

2021年:

Q. Lu, Q. Lai, Z. Chai, X. Wei, X. Xiong, H. Yi, M. Huang, W. Xu, J. Wang, Revolutionizing car body manufacturing using a unified steel metallurgy concept, Science Advances 7(49) (2021).

Y. Li, D.S. Martín, J. Wang, C. Wang, W. Xu, A review of the thermal stability of metastable austenite in steels: Martensite formation, Journal of Materials Science and Technology 91 (2021) 200-214.

C. Shen, C. Wang, M. Huang, N. Xu, S. van der Zwaag, W. Xu, A generic high-throughput microstructure classification and quantification method for regular SEM images of complex steel microstructures combining EBSD labeling and deep learning, Journal of Materials Science and Technology 93 (2021) 191-204.

C. Shen, C. Wang, P.E.J. Rivera-Díaz-del-Castillo, D. Xu, Q. Zhang, C. Zhang, W. Xu, Discovery of marageing steels: machine learning vs. physical metallurgical modelling, Journal of Materials Science and Technology 87 (2021) 258-268.

X. Wei, Z. Chai, Q. Lu, J. Hu, Z. Liu, Q. Lai, J. Wang, W. Xu, Cr-alloyed novel press-hardening steel with superior combination of strength and ductility, Mater Sci Eng A 819 (2021).

X. Yan, J. Hu, H. Yu, C. Wang, W. Xu, Unraveling the significant role of retained austenite on the dry sliding wear behavior of medium manganese steel, Wear 476 (2021).

Z. Chai, J. Hu, C. Wang, L. Wang, W. Sun, S. van der Zwaag, W. Xu, Effect of Nb on Microstructural Evolution and Mechanical Properties of Hot-Rolled Quenching and Partitioning Steels Containing Bainite, Steel Res Int 92(12) (2021).

S. Chen, J. Hu, L. Shan, C. Wang, X. Zhao, W. Xu, Characteristics of bainitic transformation and its effects on the mechanical properties in quenching and partitioning steels, Mater Sci Eng A 803 (2021).

J. Hu, K.K. Liu, L. Ma, R.D.K. Misra, W.N. Zhang, H.C. Du, W. Xu, Significant Improvement in Strength and Toughness of Nanoscale Precipitate–Strengthened Steel by Direct Quenching and Tempering Process, Steel Res Int 92(2) (2021).

Z.G. Jia, J. Hu, N. Xu, C. Liu, L.Y. Wang, C.C. Wang, W.H. Sun, W. Xu, Revealing the Effect of Microstructural Inheritance in 1.5 GPa Hot-Rolled Ultrahigh Strength Q&P Steels, Metall Mater Trans A 52(7) (2021) 3140-3151.

C. Shen, X. Wei, C. Wang, W. Xu, A deep learning method for extensible microstructural quantification of DP steel enhanced by physical metallurgy-guided data augmentation, Mater Charact 180 (2021).

C.C. Wang, C.G. Shen, Z. Zhang, W. Xu, Simulation and verification of core–shell MC carbide design in Fe–C–Ni–V–Ti steel, J Iron Steel Res Int 28(1) (2021) 58-65.

J. Wang, M. Huang, J. Hu, C. Wang, W. Xu, EBSD investigation of the crystallographic features of deformation-induced martensite in stainless steel, Journal of Materials Science and Technology 69 (2021) 148-155.

J. Wang, C. Wang, M. Huang, J. Hu, W. Xu, The Effects and Mechanisms of Pre-Deformation with Low Strain on Temperature-Induced Martensitic Transformation, Jinshu Xuebao/Acta Metallurgica Sinica 57(5) (2021) 575-585.

X. Yan, J. Hu, L. Wang, Z. Chai, W. Sun, W. Xu, The coupled effect of thermal and mechanical stabilities of austenite on the wear resistance in a 0.2C–5Mn-1.6Si steel down to cryogenic temperatures, Wear 486-487 (2021).

Q. Zhang, D. Ren, Z.P. Liu, C.C. Wang, J. Huang, W. Xu, Composition and processing of direct-quench hot rolled steels with ultrahigh strength exceeding GPa, J Iron Steel Res Int 28(6) (2021) 703-712.

T. Zhang, J. Hu, C. Wang, Y. Wang, W. Zhang, H. Di, W. Xu, Effects of deep cryogenic treatment on the microstructure and mechanical properties of an ultrahigh-strength TRIP-aided bainitic steel, Mater Charact 178 (2021).

Z. Zhang, Z. Xu, C. Wang, S. Liu, Z. Yang, Q. Zhang, W. Xu, Molecular dynamics-guided quality improvement in the femtosecond laser percussion drilling of microholes using a two-stage pulse energy process, Opt Laser Technol 139 (2021).

Z. Zhang, Z. Yang, C. Wang, Q. Zhang, S. Zheng, W. Xu, Mechanisms of femtosecond laser ablation of Ni3Al: Molecular dynamics study, Opt Laser Technol 133 (2021).

K. Zhu, T. Zhang, Q. Cui, C. Wang, W. Xu, Effect of Ta and Ti on Modified Reduced Activation Ferritic/Martensitic Steels with a Thermo-mechanical Control Process, Steel Res Int 92(3) (2021).

Y. Borisova, D. Yuzbekova, A. Mogucheva, W. Xu, Characterization of the spatiotemporal behavior of the PLC bands in austenitic steel during deformation at elevated temperature, Mater Lett 304 (2021).

Z. Hou, J. Min, J. Wang, Q. Lu, Z. He, Z. Chai, W. Xu, Effect of Rapid Heating on Microstructure and Tensile Properties of a Novel Coating-Free Oxidation-Resistant Press-Hardening Steel, JOM 73(11) (2021) 3195-3203.

S. Wang, H. Pan, X. Wang, J. Yin, X. Hu, W. Xu, P. Wang, Atomic insights into the quasi-elastic response in shock reloading of shocked metals, Results in Physics 31 (2021).

发明专利:

序号 |

专利名称 |

类别 |

申请/授权日期 |

申请/授权号 |

1 |

Method for manufacturing a high-strength steel sheet and sheet obtained by the method |

国际发明专利(欧盟) |

2020.05.13 |

EP3164513A2 |

2 |

Method for manufacturing a high-strength steel sheet having improved formability and sheet obtained |

国际发明专利(欧盟) |

2019.04.24 |

EP3164515A2 |

3 |

一种厚规格热成型钢的制备方法、热轧钢板及热成型钢 |

国家发明专利 |

2022.02.22 |

CN113832407B |

4 |

一种1700MPa级高Cr-Si薄规格热成型钢的热轧制备方法 |

国家发明专利 |

2022.03.01 |

CN113846272B |

5 |

一种低碱度免涂层热成型钢连铸用保护渣 |

国家发明专利 |

2022.02.22 |

CN113857448B |

6 |

一种免涂层热成形钢的合金加入方法 |

国家发明专利 |

2022.04.22 |

CN114032473B |

7 |

基于物理冶金学指导下机器学习的超高强不锈钢设计方法 |

国家发明专利 |

2019.07.31 |

CN110442954A |

8 |

一种分子动力学指导的机器学习的激光制孔结果预测方法 |

国家发明专利 |

2021.04.06 |

CN113032909A |

9 |

一种基于EBSD与深度学习方法的钢铁材料性能预测方法 |

国家发明专利 |

2021.04.06 |

CN113033106A |

10 |

基于物理冶金学指导下机器学习的低活化钢的设计方法 |

国家发明专利 |

2019.07.31 |

CN110415769A |

11 |

一种基于物理指导的机器学习算法的钢铁材料设计方法 |

国家发明专利 |

2019.07.31 |

CN110428876A |

12 |

基于物理冶金学指导下机器学习的Q&P钢的设计方法 |

国家发明专利 |

2019.07.31 |

CN110442953A |

13 |

一种含噪声EBSD数据中无噪声相图的人工智能预测方法 |

国家发明专利 |

2020.08.14 |

CN111915603A |

14 |

一种结合EBSD与深度学习方法的钢铁材料组织定量化方法 |

国家发明专利 |

2020.08.14 |

CN111915602A |

15 |

一种基于力学理论指导迁移学习的钢铁材料疲劳性能预测方法 |

国家发明专利 |

2021.04.06 |

CN113033105A |

软件著作权:

序号 |

软件著作名称 |

类别 |

发表日期 |

登记号 |

1 |

基于EBSD图像的残余奥氏体预测平台V1.0 |

国家计算机软件著作权 |

2019.03.01 |

2019SR1061316 |

2 |

基于人工智能技术的马氏体时效钢力学性能预测平台V1.0 |

国家计算机软件著作权 |

2019.03.01 |

2019SR1061319 |

荣誉奖励

序号 |

奖项 |

年份 |

获奖等级 |

来源 |

获奖人 |

1 |

中国金属学会冶金青年科技奖 |

2020 |

一等奖 |

中国金属学会 |

徐伟 |

2 |

NSFC-RS中英牛顿高级学者 |

2019 |

-- |

国家自然科学基金委员会 |

徐伟 |

3 |

“万人计划”创新领军人才 |

2019 |

-- |

中组部 |

徐伟 |

4 |

中青年科技创新领军人才 |

2018 |

-- |

科技部 |

徐伟 |

5 |

“兴辽英才计划”青年拔尖人才 |

2019 |

-- |

辽宁省政府 |

徐伟 |

6 |

冶金科学技术奖 |

2017 |

二等奖 |

中国金属学会 |

徐伟 |

7 |

辽宁省技术发明奖 |

2017 |

一等奖 |

辽宁省政府 |

徐伟 |

8 |

辽宁省科技进步奖 |

2020 |

三等奖 |

辽宁省政府 |

徐伟、王晨充 |

9 |

2011钢铁共性技术协同创新中心青年新秀 |

2019 |

一等奖 |

钢铁共性技术协同创新中心 |

王晨充 |

10 |

东北大学优秀博士后 |

2018 |

-- |

东北大学 |

王晨充 |