Recently, the paper titled Crystallographic Structure and Properties of Novel Quaternary Nanolaminated Rare-earth-Cr-based I-MAX Phases was published in the internationally renowned journal Acta Materialia. It is the research result of Professor Cui Weibin's team from NEU. Sun Shuli, a doctoral candidate of NEU, is the first author of the paper, and Professor Cui Weibin is the corresponding author.

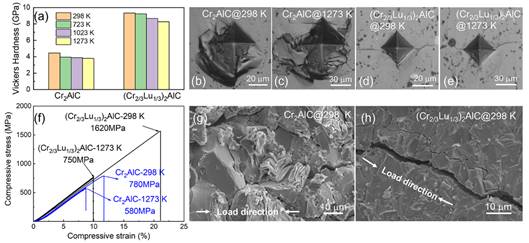

The crystal structure of compound (Cr2/3R1/3)2AlC is orthogonal, and the Cmcm space group, the rare earth atoms R and Cr are arranged alternately in the R-Cr layer and protrude from the R-Cr layer towards the Al layer atom. The synthesized novel compound (Cr2/3R1/3)2AlC exhibits a specific magnetic phase transition behavior at low temperatures, and shows high hardness and compressive strength at both room and high temperatures (Figure 1), as well as excellent wear resistance. The mechanism of the transition from an orthogonal structure to a monoclinic structure (Figure 2) is further studied after the bulk (Cr2/3R1/3)2AlC sample is compressed at high temperature.

This study has introduced rare earth atoms into the lattice of the traditional MAX phase of compound Cr2AlC, and synthesized a series of novel layered compounds with ordered space-occupying rare earth for the first time. It has endowed the material with new magnetic properties and significantly improved the hardness, compressive strength, wear resistance and other physical properties of materials, providing a new idea for the design and synthesis of novel layered compounds. Additionally, it has provided an important theoretical basis for expanding the potential applications of i-MAX phase layered compounds. Thanks would be given to the Analysis and Testing Center of NEU for its support to the structural characterization work in this study.

The paper links: https://doi.org/10.1016/j.actamat.2022.118479

Figure 1. Comparison of hardness and compressive strength at different temperatures between Cr2AlC and (Cr2/3Lu1/3)2AlC (a) Vickers hardness comparison diagram; (b)-(e) indentation morphology comparison diagram; (f) compressive strength-strain comparison diagram; (g) and (h) compressive fracture morphology comparison diagram.

Figure 2. Crystal structure characterization after high temperature compression. HAADF image of orthogonal and monoclinic structures corresponding to (Cr2/3Lu1/3)2AlC[110]o crystal orientation and corresponding atomic arrangement diagram