Recently, Prof. Zhenyu Liu's team at the State Key Laboratory of Rolling and Automation of NEU has published their latest research results in Advanced Functional Materials, the top journal in the field of materials science, under the title of “A Novel B2 Precipitate Gives High Strength and High Impact Toughness to Bcc-Structured Cryogenic Steels”. The study discovered a new molybdenum-rich B2 nanoprecipitate phase, which balances high strength and high toughness of steel at a temperature of 77K (-196°C), which is extremely low, and opens up a new way of designing the organization of steel materials for clean energy at extremely low temperature.

The transportation and storage of clean energy sources such as liquefied natural gas (LNG) operate at extremely low temperatures. With the mega-scale of energy projects (LNG storage tanks up to 270,000 m³), to ensure their safe operation, steel must be both high strength and possess excellent impact toughness at extremely low temperatures of 77K. For a long time, adding a large amount of precious Ni elements (e.g. 9Ni steel) to body-centered cubic (bcc) structural steel has been regarded as the only way to realize the above stringent performance requirements. The frontiers of low-temperature steel research at home and abroad lie in innovating toughening methods and reducing the production cost of 9Ni steels through new organization design.

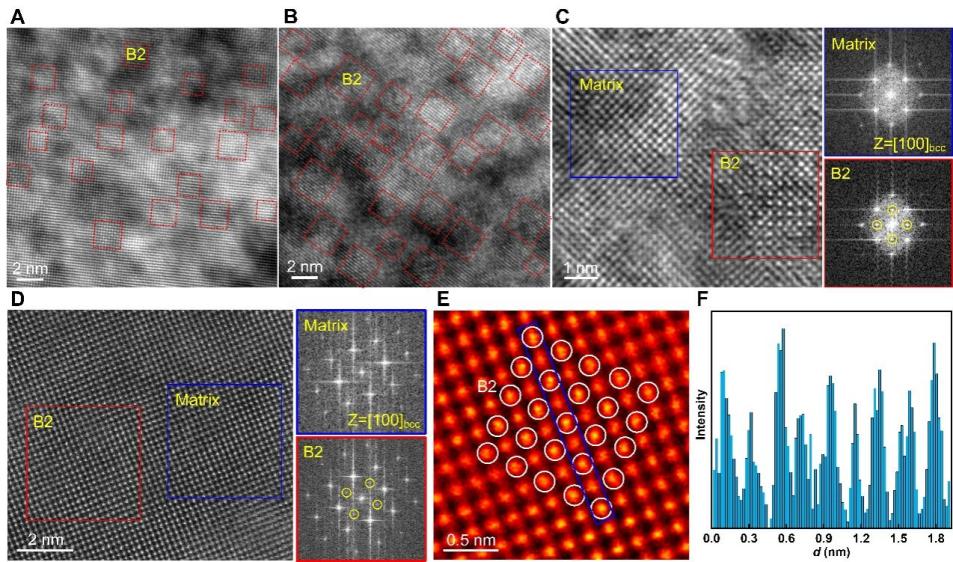

The research team designed a new 6.5NiMo steel containing 6.5%Ni-0.2%Mo and prepared a large number of high-density nanoscale B2 precipitated phases (Fig. 1). It is generally believed that B2 precipitated phases have good precipitation strengthening effect, but they are very prone to brittle fracture under very low-temperature load impact conditions. The research team found for the first time that the Mo-enriched B2 nanodeposited phase is not only fully co-compartmentalized with the steel matrix, but also can be plastically deformed at very low temperatures, which significantly improves the very low-temperature toughness of the steel while maintaining its high strength. This study breaks through the bottleneck of strength and toughness balance, which is common in precipitation-strengthened steels, and enables 6.5NiMo steel to outperform conventional 9Ni steel at very low temperatures (Fig. 2), while also dramatically reduces the amount of costly Ni elements and lowers the production cost.

Currently, 6mm to 50mm thick 6.5NiMo steel plates have been fabricated under industrial conditions and successfully applied to the construction of marine LNG tanks and other large-scale cryogenic storage tanks. This research provides a new way for toughening steel materials, which is of great theoretical significance and practical value for promoting the preparation and application of greening high-performance steel materials for clean energy.

Dr. Qiyuan Chen, Prof. Shuai Tang and Associate Researcher Weina Zhang of the State Key Laboratory of Rolling and Automation are the co-first authors of the paper, and NEU is the first completion unit.

Fig. 1 TEM characterization of the novel nano-B2 precipitated phase

Fig. 2 Comparison of the toughness properties of the newly developed steel with other steels for very low temperatures