Recently, Professor Xu Dake’s research group of Professor Wang Fuhui’s team from the School of Materials Science and Engineering NEU, and Professor Lu Yiping of Dalian University of Technology have made important progress in the development and design of high-entropy alloys with mechanics, antimicrobial, antiviral, anti-microbial corrosion performances, and the research results were published in the internationally renowned journal Advanced Functional Materials (DOI: 10.1002/adfm.202419467) under the title of "A Novel Cu and Ag Bearing High-Entropy Alloy with Remarkable Antibacterial, Antiviral and Anti-microbial Corrosion Performances". The first author of the paper is Associate Professor Zhou Enze, and the corresponding authors are Professor Xu Dake, and Professor Lu Yiping of Dalian University of Technology.

The adhesion of bacteria and viruses on the surface of metal materials can easily lead to food contamination and viral infections, and the formation of corrosive biofilms can also accelerate the microbial corrosion of alloy materials such as marine steel and oil pipelines. Microbial corrosion is also one of the urgent problems to be solved in the current materials field, and the global economic losses caused by microbial corrosion accounted for about 20% of the total corrosion losses. Therefore, from the perspective of alloy materials, it is especially critical to develop new alloy materials that have their own antibacterial, antiviral and microbial corrosion resistance. So far, a series of antibacterial stainless steel materials have been successfully developed, but for stainless steel materials, in order to achieve a good antimicrobial effect while maintaining the corrosion resistance and mechanical properties of the material, the maximum content of copper that can be added is usually no more than 5wt%, which makes it difficult to play the excellent characteristics of the elements in the alloy composition, so that the development of antimicrobial alloy materials is limited to some extent. To address this challenge, the development of high-entropy alloys with multiple principal elements has been identified as an effective strategy to improve the antimicrobial, antiviral and microbial corrosion resistance of alloyed materials.

Fig. 1 Preparation (a), organization structure (b), tensile stress-strain curves (c), mechanical property test results (d) and Vickers hardness (e) of high-entropy alloys

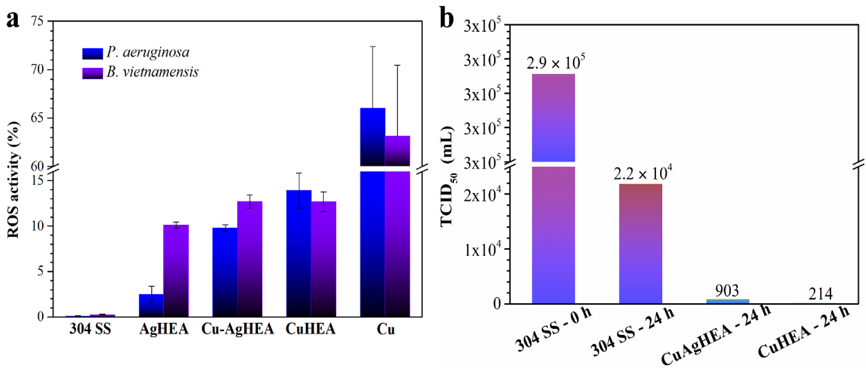

Two new types of high-entropy alloys were designed in this work, namely CoCrCu0.3FeNiAg (1.8 wt.%) (Cu-AgHEA) and CoCrFeNiAg0.6 (AgHEA). Their yield strength, hardness and elongation don't vary much from each other and are all superior to that of the CoCrCuFeNi high-entropy alloy (CuHEA) containing only copper. Among them, the yield strength of Cu-AgHEA is approximately 400 MPa, which is 1.3 times higher than that of CuHEA and 1.9 times higher than that of 304 stainless steel. Due to the synergistic release of Cu and Ag ions, Cu-AgHEA generates a higher concentration of reactive oxygen species (ROS), accelerating the damage to bacterial cells. Its antibacterial effect on marine bacteria is far superior to that of AgHEA, with an antibacterial rate reaching 99.9%. The corrosion resistance and microbiologically influenced corrosion resistance of Cu-AgHEA are also far superior to those of CuHEA. After 7 days of immersion in the presence of bacteria, the corrosion current densities are 0.7 μA cm−2(Cu-AgHEA) and 1.8 μA cm−2(CuHEA) respectively. In addition, Cu-AgHEA has significant antiviral properties. After 24 hours of co-cultivation, about 99% of the COVID-19 virus (SARS-CoV-2) on the surface of Cu-AgHEA can be killed, making it non-infectious. The above research results provide new ideas for promoting the design of new alloy materials integrating structure and function, with broad potential application prospects.

Fig. 2 ROS yield (a) and resistance to the COVID-19 virus (b) after co-cultivation of high-entropy alloys with microorganisms

The above work was supported by the National Science Fund for Distinguished Young Scholars, the China Baowu Low-Carbon Metallurgical Innovation Fund, the Young Talent Support Project of the China Association for Science and Technology, Youth Fund of the National Natural Science Foundation of China and the National Key Research and Development Program.